The Scientific Research Association for Kakishibu and Kakitannin ( SRAKK )

The Scientific Research Association for

Kakishibu and

Kakitannin (SRA

KK) is

composed of volunteer researchers, fruit growers and general citizens, who have an interest in the astringent substances in persimmon fruit. The association was founded in Kyoto in May 2014, through a subsidy for promoting local contribution to business from Kyoto Prefectural University.

The main activity of this group is to enhance the exchange of information and technology through the following;

(1) expansion of production of persimmon fruit for making persimmon tannin juice containing astringent substances

(2) improvement of productivity and quality of persimmon tannin juice (Kakishibu)

(3) development of practical uses of persimmon tannin juice (Kakishibu); revitalization of the present Kakishibu factories and creation of new Kakitannin industry.

(4) inheritance, education, and publication of Kakishibu culture in traditional Japanese society

SRAKK holds lectures, exhibitions and workshops on an irregular basis, and irregularly publishes a SRAKK report, news or journal.. SRAKK’s Home Page can be found here.

( http://kakishibu.tannin.info ) SRAK

K’s membership is open to everyone with an interest in the various aspects of

Kakishibu and

Kakitannin. Some of the researchers within SRAKK

are aiming at research and development of new Kakishibu products, as well as new technologies for higher production of astringent persimmon fruit in a shorter period.

While SRAKK has the central aim of developing the Kakishibu industry, and subsequently looks to create a more friendly society on earth, by using Kakishibu in substitution for plastics from oil and coal in our daily lives. SRAKK’s wide range of activities also promote exchange between people from large cities and rural areas.

The astringent substances in persimmon fruit and Kakishibu are explained briefly below;

The fruits of the Japanese persimmon show wide variation in size, shape, and color, and are broadly classified for horticultural purposes into two major groups; astringent and non-astringent, depending on their astringency at the mature stage. The astringency of a persimmon depends on the quantity of soluble tannins in the flesh of the fruit, which accumulate in the vacuoles of specialized tannin cells.

Three commercial products from astringent fruits have been traditionally produced in Japan; 1) de-astringent fruit, 2) dried sweet fruit, and 3) Kakishibu

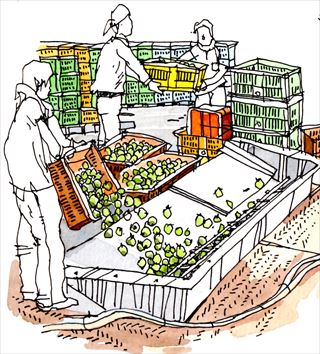

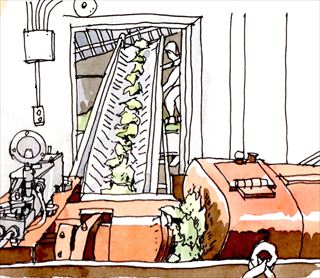

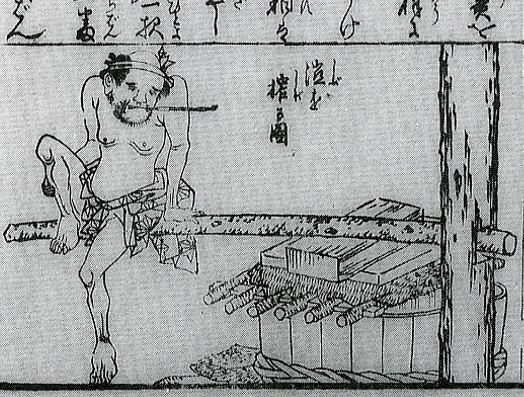

Kakishibu is produced when young and or immature green fruit of special

cultivars such as

Tennou, Turunoko, Horenbou, Saijou and

Tamura are harvested and then squeezed to get fresh juice. After that, the slightly green juice is incubated for fermentation for a long period, anywhere from half a year to three years, in order to remove sugars, amino acids and other hydrophilic impurities. This encourages the formation of

precipitate through long standing, and obtains a more clear tannin solution. This highly fermented tannin juice is called Kakishibu and is an artificial product. The color is generally dark brown-reddish and can have low levels of turbidity or none at all.

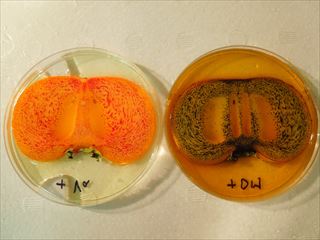

In contrast, an intact Kakitannin (an intact astringent substance), quickly prepared from green and astringent fruit, is transparent and colorless. This is a characteristic of a biological polymer compound, which has been identified as a polymer(s) of proanthocyanidin (It is composed of four kinds of catechins with a ratio of 1:2:1:2. It has two chemically distinctive characters; modification of galloyl groups and a higher molecular weight).

Kakishibu is believed to have been used for various purposes since the end of

Heian era starting 794 AD when the ancient capital city of Japan was established in Kyoto. It has had a number of applications, including as a cloth dyeing agent due to

it's distinctive red-brown color.

A notable feature of Kakishibu is the ability to bind strongly to its various chemical compounds. After coating and then drying, it can form a resin-like layer on papers and woods, excellent for water resistance.

Some other concrete examples are listed below;

1) It can prevent the corrosion of fishing nets made with natural materials such as cotton and hemp.

2) It has been traditionally used as paint for sake (a rice wine) sacks, and wooden buckets.

3) It can harden the fiber of wood and paper, prevents corrosion, and makes them waterproof and insect repellent, useful for making durable Japanese fans, umbrellas, bags, wooden cups, cloth containers and plates.

4) It can lower the density of alcohol in the blood stream after drinking.

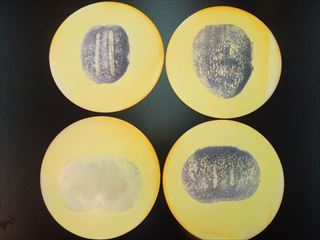

5) It can suppress the propagation of various bacteria and viruses.

6) Since it has a high affinity with proteins, it has been used as a de-proteining agent in production of rice wine and sweet cooking rice wine

Other special and practical products of Kakishibu have also been developed in recent years. One of these is the development of a cleaning solution with antiviral and antibacterial properties. Others include the addition of Kakishibu on wheat and rice flours, which can improve firmness and texture of Ramen noodles and rice cakes or sweets, and the technology to recover heavy metals, especially gold, from seawater and wastewater.

Because Kakishibu and Kakitannin have such a variety of further hidden possibilities, they are expected to be attractive materials in various fields of industry, even now.